Nano D5 Series Blower Purge

Twin Tower Desiccant Air Dryers

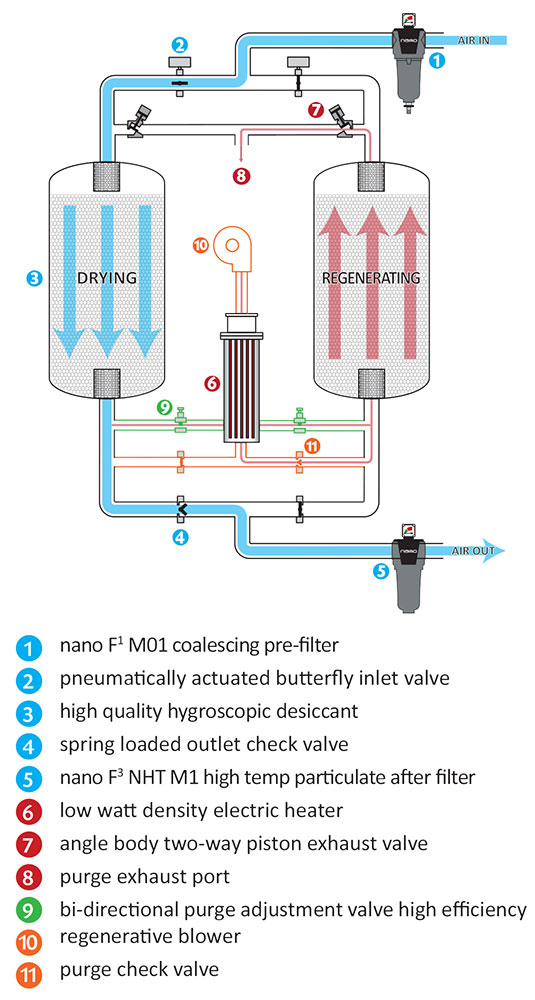

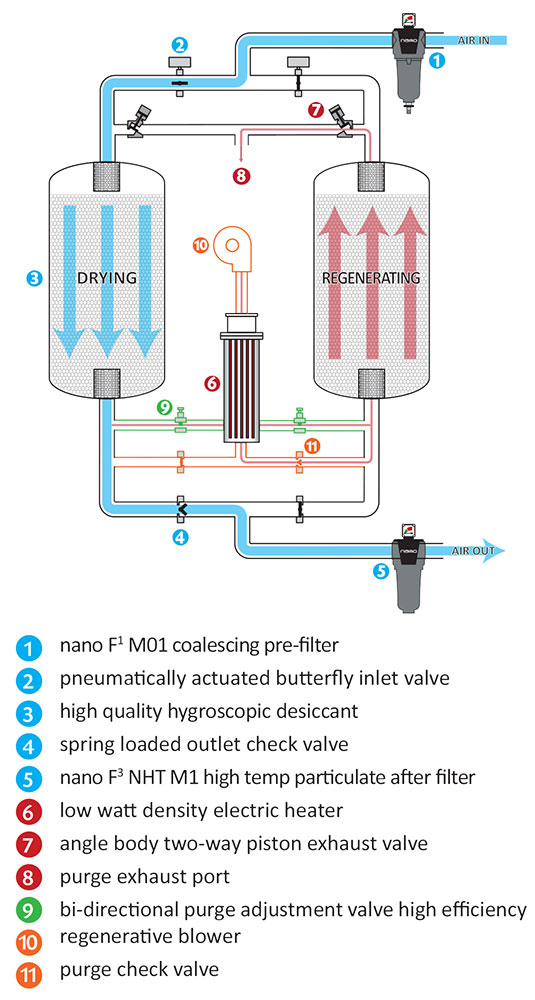

500 - 10,000 scfmThe nano D5 blower purge desiccant air dryers use a blower and an electric heater to provide heated ambient air for regeneration. With a purge air usage to only 2% (averaged over the cycle) and an option for zero purge operation, these dryers off er the lowest cost of operation for most applications.

Nano D5 NBP Blower Purge twin tower desiccant air dryers reliably give you:

• advanced PLC controls allow you to monitor the operation of the dryer through an easy to use digital display.

• multiple thermocouples control regeneration and provide constant temperature display.

• secondary heater contactor provides protection against overheating in the event of a primary contactor failure.

• visual alarm lights and step by step diagnostics simplify troubleshooting.

• selectable “Dry Air Cooling” mode lets you choose between maximum performance and maximum energy savings depending on the needs of your application.

• rugged field proven digitally controlled dual acting high performance butterfly valves and stainless steel spring return wafer check valves ensure long operating life and minimum maintenance.

• nano M01 coalescing pre filters and NHT M1 high temperature after filters with high quality hygroscopic desiccant ensure low pressure drop and consistent dew point performance.

• nano understands that every customer and every application is different. That is why we provide a wide range of available options to customize your dryer to your specific needs.

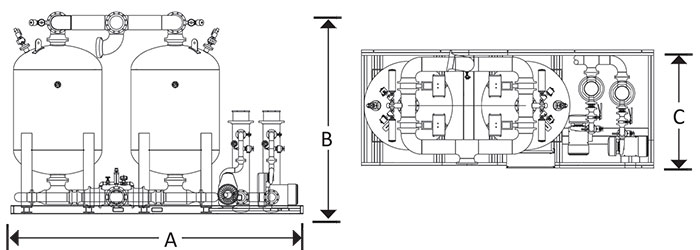

Model(s): NBP 500, NBP 650, NBP 800, NBP 1000, NBP 1250, NBP 1500, NBP 2000, NBP 2500, NBP 3000, NBP 3500, NBP 4000, NBP 5000, NBP 6000, NBP 7000, NBP 8000, NBP 9000, NBP 10000

(1) 2” and below are NPT(F) threaded. 3” and above are flanged. All units with 3” piping will be ANSI welded pipe and the filter connections will be flanged

(2) at an inlet of 100 psig and 100°F. For all other inlet conditions refer to the correction factors

(3) recommended for all applications

(6) per ISO 8573.1:2010

➤Click Here for Pressure & Temperature Correction Factors Chart

• specifically designed for a long and dependable operating life in harsh industrial environments.

• metal on metal seats for reliable high temperature operation.

• dependable stainless steel spring return check valves provide worry-free operation and minimal maintenance.

• pneumatic actuators ensure precise proportional control and a bubble tight seal.

• stainless steel and Teflon® seats in a reliable and low pressure drop design.

• purge flow is field adjustable with this precision valve with visual setting indication.

• easily adjust the purge flow to match the operating conditions.

• synoptic display with visual dryer operation.

• alarm indication and description.

(1) 2” and below are NPT(F) threaded. 3” and above are flanged. All units with 3” piping will be ANSI welded pipe and the filter connections will be flanged

(2) at an inlet of 100 psig and 100°F. For all other inlet conditions refer to the correction factors

(3) recommended for all applications

(6) per ISO 8573.1:2010

➤Click Here for Pressure & Temperature Correction Factors Chart

How It Works

• regeneration circuit is fully insulated for maximum efficiency.• specifically designed for a long and dependable operating life in harsh industrial environments.

• metal on metal seats for reliable high temperature operation.

• dependable stainless steel spring return check valves provide worry-free operation and minimal maintenance.

• pneumatic actuators ensure precise proportional control and a bubble tight seal.

• stainless steel and Teflon® seats in a reliable and low pressure drop design.

• purge flow is field adjustable with this precision valve with visual setting indication.

• easily adjust the purge flow to match the operating conditions.

• synoptic display with visual dryer operation.

• alarm indication and description.

Options & Accessories

• Dew Point Monitors○ integral energy saving outlet dew point control & display

○ stand alone portable dew point monitor

• Filter + bypass options

○ three (3) valve block & bypass

• Electrical protection upgrades

○ NEMA 4 electrical protection

○ NEMA 4X electrical protection

○ NEMA 7 electrical protection

• Other options & upgrades

○ low ambient (< 32°F) temperature protection

○ visual moisture indicator

○ failure to shift alarm

○ run time hour meter

○ additional pressure gauges (each)

○ additional temperature gauges (each)

○ CSA approval for Canadian applications

○ 400 Volt 3 Phase 50Hz controls

○ 575 Volt 3 Phase 60 Hz controls

○ tower & hot piping insulation

○ NEMA 4 fusible disconnect

○ stainless steel control tubing

Click for Larger View

Click for Larger View Click for Warranty Policy Summary

Click for Warranty Policy Summary

Click Here to view the mdi Line Sheet.