Nano R1 Series Cycling Refrigerated

Compressed Air Dryers

20 - 2,000 scfmnano NXC R1 Series uses a patented heat exchanger comprised of a separate air to air exchanger and an air to refrigerant exchanger immersed in an environmentally friendly and highly efficient silica dry thermal mass. This unique combination provides the best dew point performance, the fastest response times if demand increases suddenly and the lowest power consumption across the entire spectrum of operation.

Nano R1 NXC Cycling Refrigerated Compressed Air Dryers reliably give you:

• lower electrical consumption from 0% to 100% duty cycle and low pressure drop.

• thanks to the silica dry mass, no overnight precooling of thermal mass is required.

• fully packaged into a simple compact design, NXC will fit into the smallest spaces.

• all panels can be removed to facilitate maintenance.

• nano filters to improve compressed air quality and to ensure trouble-free operation.

• powder coated galvanized steel panels are corrosion resistant.

• water cooled condensers - optional.

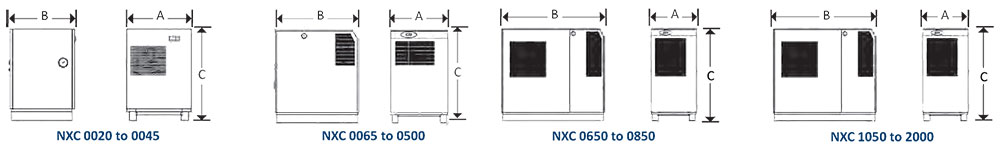

Model(s): NXC 0020, NXC 0030, NXC 0045, NXC 0065, NXC 0090, NXC 0110, NXC 0130, NXC 0165, NXC 0200, NXC 0265, NXC 0325, NXC 0400, NXC 0500, NXC 0650, NXC 0850, NXC 1050, NXC 1300, NXC 1600, NXC 2000

(1) ½" to 3” are NPT threaded connections, 4” are supplied with ANSI flanged connections

(2) rated flow capacity: conditions for rating dryers are in accordance with ISO7183 (Option A2). Compressed air at dryer inlet: 100 psig (7 bar) and 100°F (38°C); ambient air temperature: 100°F (38°C); operating on 60Hz power supply

(3) nominal absorbed power at rated operating conditions using 115/1/60 or 460/3/60 power supply (as applicable). for absorbed power at other voltages or conditions, contact sales@nanosales.com

(4) specify voltage requirements when ordering. For 575V applications, please contact sales@nanosales.com for assistance

Models NXC 0020 - NXC 0165: UL STD 60335-1 & 60335-2-40 / CSA STD C22.2

➤Click Here for Pressure & Temperature Correction Factors Chart

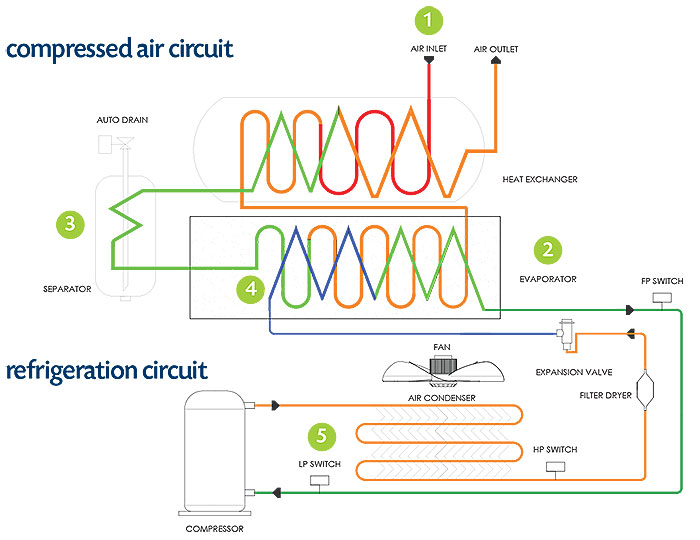

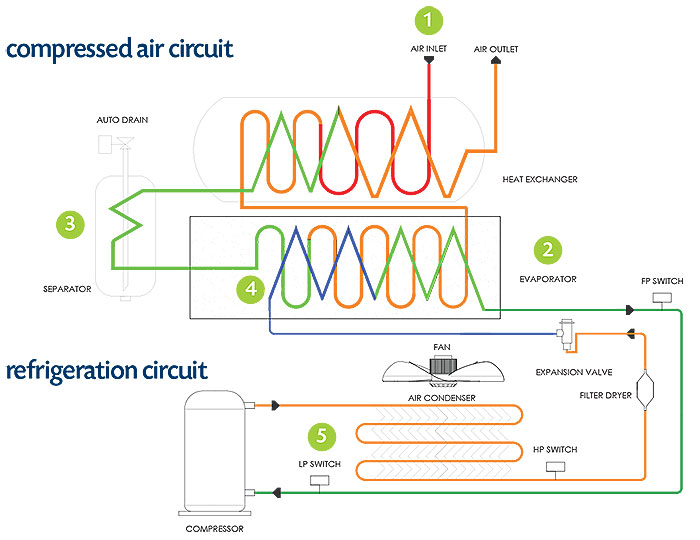

2. Precooled compressed air then enters the air to refrigerant evaporator where it reaches its coldest point and achieves its lowest dew point.

3. Condensed moisture is removed by an integrated moisture separator and condensate drain prior to reentering the air to air heat exchanger where incoming hot air reheats the exiting cold compressed air.

4. The refrigerant comes into direct contact with both the silica dry mass and compressed air inside the air to refrigerant evaporator.

5. If demand drops and compressed air flow rate is reduced, the refrigerant compressor cycles off and the silica dry mass is employed to continue drying the air. THIS is dual transfer technology.

(1) ½" to 3” are NPT threaded connections, 4” are supplied with ANSI flanged connections

(2) rated flow capacity: conditions for rating dryers are in accordance with ISO7183 (Option A2). Compressed air at dryer inlet: 100 psig (7 bar) and 100°F (38°C); ambient air temperature: 100°F (38°C); operating on 60Hz power supply

(3) nominal absorbed power at rated operating conditions using 115/1/60 or 460/3/60 power supply (as applicable). for absorbed power at other voltages or conditions, contact sales@nanosales.com

(4) specify voltage requirements when ordering. For 575V applications, please contact sales@nanosales.com for assistance

Models NXC 0020 - NXC 0165: UL STD 60335-1 & 60335-2-40 / CSA STD C22.2

➤Click Here for Pressure & Temperature Correction Factors Chart

How It Works

1. Hot, moist compressed air enters the separate air to air heat exchanger where it is precooled.2. Precooled compressed air then enters the air to refrigerant evaporator where it reaches its coldest point and achieves its lowest dew point.

3. Condensed moisture is removed by an integrated moisture separator and condensate drain prior to reentering the air to air heat exchanger where incoming hot air reheats the exiting cold compressed air.

4. The refrigerant comes into direct contact with both the silica dry mass and compressed air inside the air to refrigerant evaporator.

5. If demand drops and compressed air flow rate is reduced, the refrigerant compressor cycles off and the silica dry mass is employed to continue drying the air. THIS is dual transfer technology.

Pre & After Filtration Options

recommended filtration matches dryer inlet/outlet connection

Click for Larger View

Click for Larger View Click for Warranty Policy Summary

Click for Warranty Policy Summary

Click Here to view the mdi Line Sheet.